Connect your catalog in minutes to start tracking daily sales, ads, and inventory with D-1 insights—powered by an approved Walmart Marketplace solutions provider.

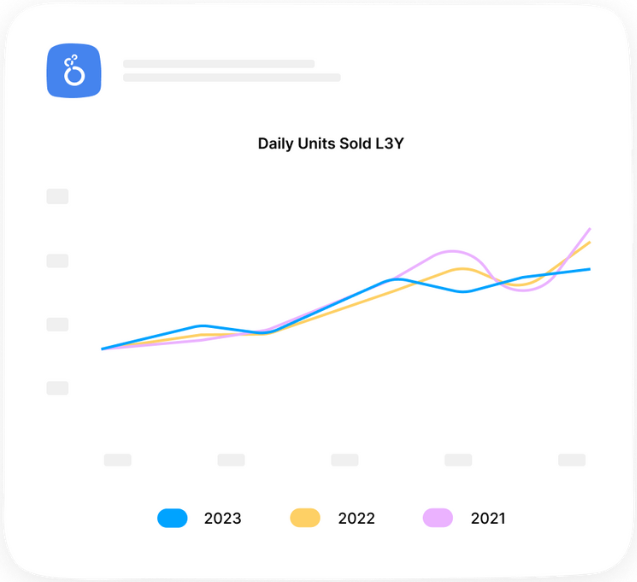

Track daily Walmart revenue and sales velocity (D-1) in your favorite BI tool.

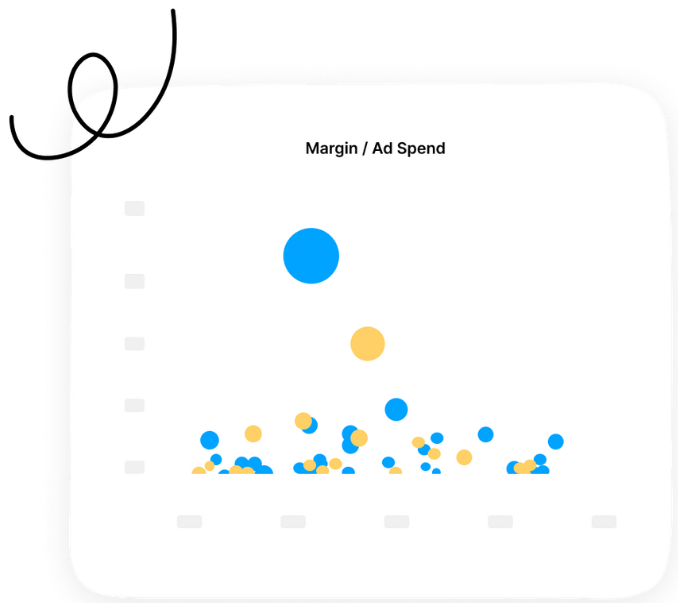

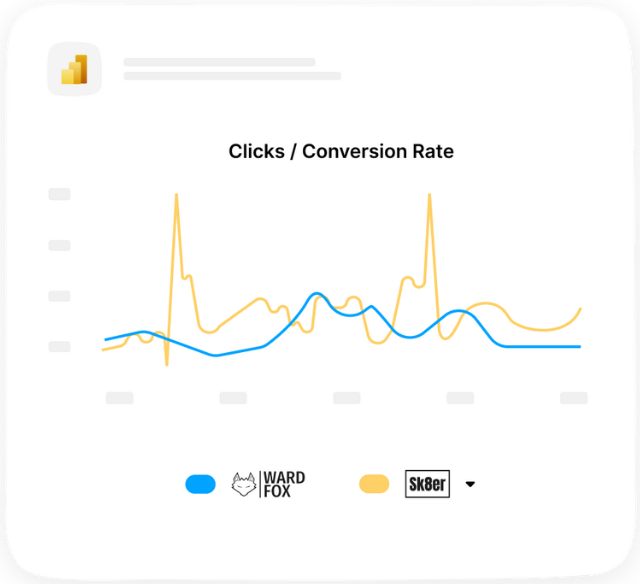

Pinpoint under-performing keywords and bids to lower CAC and lift ROAS across Walmart Connect campaigns.

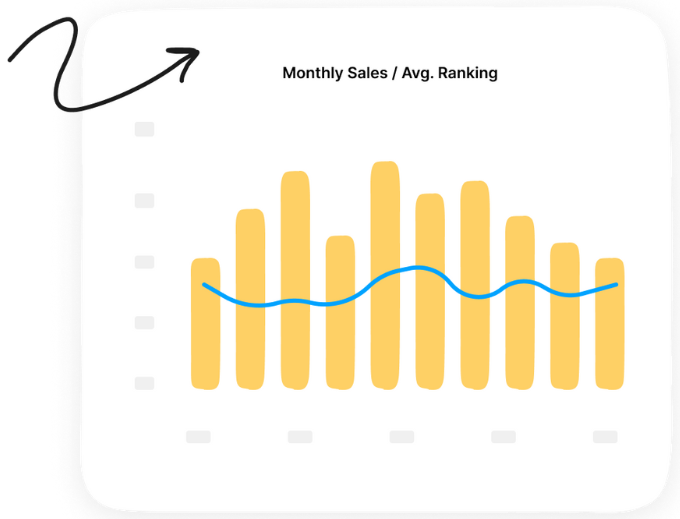

Daily keyword ranks reveal quick wins to boost organic traffic without extra ad spend.

Spot price-parity issues and Buy Box losses daily before they hurt sales.

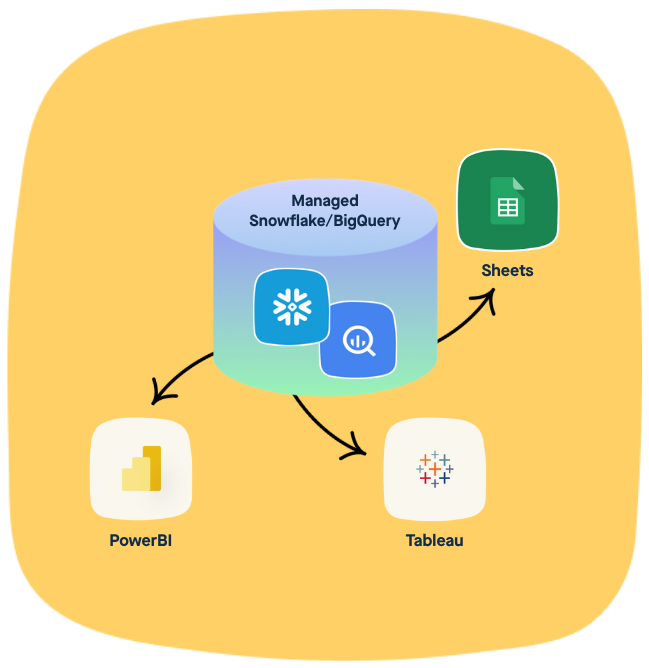

Stream modeled Walmart data to Snowflake, BigQuery, or Databricks via secure connectors for custom analytics.

Monitor competitor prices and uncover undercutting or margin-boosting opportunities to keep your Buy Box and profits intact.

“DataHawk had all the data and features we needed, with analytics and reporting capabilities we couldn’t find elsewhere. We were also impressed with the level of expertise, support and follow-up from the DataHawk team.”

“DataHawk is more than just a marketplace analytics tool; it’s a key partner in helping us build our business platform.”

“DataHawk is foundational to us understanding what’s going on in the business. It’s helping us see things that we wouldn’t see before.”

Messy portals, manual exports, and scattered reports turn Walmart operations into guesswork. Centralizing sales, ads, inventory, and SEO into one database turns chaos into clarity. Just clean data, ready for your BI stack—so blind spots disappear and growth can scale.

From fragmented

To unified

From inefficient

To productive

From stalled

To progressing

From slow-moving

To streamlined

From delayed

To responsive

From limited

To comprehensive

Yes, DataHawk is an official Walmart partner and uses Walmart APIs and meets strict security and performance standards set by Walmart Marketplace.

Ninety days of sales and ad history are backfilled automatically, and fresh data syncs every 24 hours.

We deliver all the analytics needed to manage your bid, you keep final control.

Yes—your data is hosted in industry leading databases Snowflake, BigQuery, and DataBricks which can be connected to your favorite BI tool (incl. Power BI, Tableau, Looker and Sheets).

All data history is retained throughout our partnership. You own what you store and export.

Find out how DataHawk helps you optimize your eCommerce from A-to-Z

ECommerce analytics just got a whole lot more powerful and easier. Learn more about our unified analytics platform powered by AI.